Customizing CNC Machines for Specific Needs: Tailoring Solutions

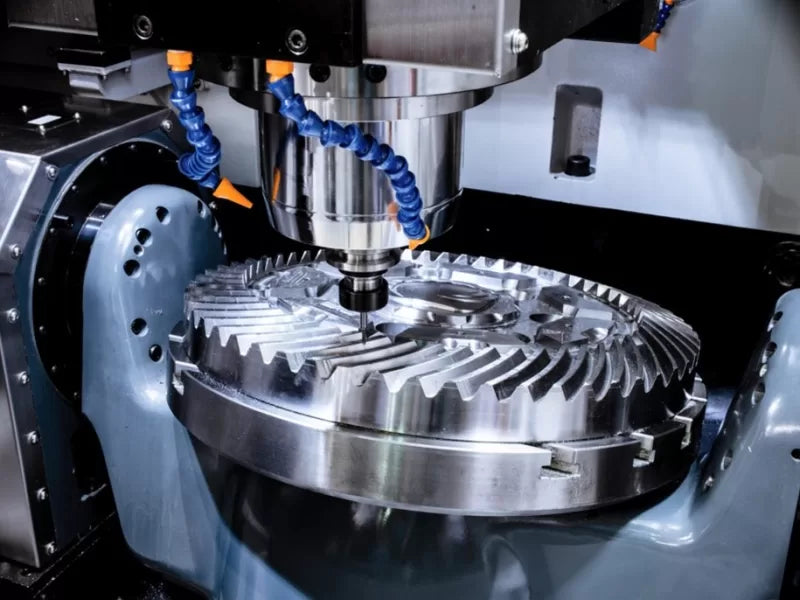

In the ever-evolving landscape of manufacturing, precision, efficiency, and adaptability are paramount. To meet the diverse needs of industries ranging from automotive to aerospace, the role of CNC (Computer Numerical Control) machines has become indispensable. These machines, with their ability to automate and execute complex machining operations with precision, have revolutionized production processes worldwide. However, in a world where one size rarely fits all, the demand for customizable CNC machines tailored to specific needs and preferences is on the rise.

In today’s dynamic manufacturing landscape, the ability to customize CNC (Computer Numerical Control) machines to meet specific requirements has become increasingly vital. Whether it’s achieving precise tolerances, enhancing productivity, or adapting to unique materials, the demand for tailored solutions is on the rise. At Jaewoo Machines, we understand the importance of customization in optimizing manufacturing processes. In this blog post, we’ll delve into the significance of customizing CNC machines for specific needs and explore how our range of CNC, VMC (Vertical Machining Center), HMC (Horizontal Machining Center), and DTC (Double Turret Turning Center) machines can address diverse manufacturing challenges.

Understanding the Need for Customization

Every manufacturing operation is unique, with its own set of challenges and objectives. Off-the-shelf CNC machines may not always suffice to meet the exact requirements of a particular application. This is where customization comes into play. By tailoring CNC machines to specific needs, manufacturers can unlock a host of benefits:

Precision Engineering: Achieving precise tolerances is crucial in many industries, such as aerospace and medical device manufacturing. Customizing CNC machines allows for fine-tuning parameters to ensure the highest level of accuracy in machining processes.

Optimized Productivity: By aligning CNC machine capabilities with specific production requirements, manufacturers can streamline workflows and maximize productivity. Customizations such as automated tool changers, optimized tool paths, and advanced control systems can significantly enhance efficiency.

Material Adaptability: Different materials present unique challenges in machining, whether it’s the hardness of metals or the delicacy of composites. Customized CNC machines can be equipped with specialized cutting tools, coolant systems, and machining strategies tailored to specific materials, enabling optimal results.

Flexibility and Versatility: The ability to quickly adapt to changing production needs is a competitive advantage in today’s fast-paced market. Customized CNC machines offer flexibility to handle a wide range of tasks, from prototyping to high-volume production, without the need for extensive retooling.

Tailoring Solutions with Jaewoo Machines

At Jaewoo Machines, we take pride in our ability to deliver tailor-made solutions that empower manufacturers to achieve their goals. Our extensive lineup of CNC, VMC, HMC, and DTC machines is designed with versatility and customization in mind. Here’s how we can customize our machines to address specific needs:

Advanced Control Systems: Our CNC machines are equipped with state-of-the-art control systems that offer unparalleled precision and flexibility. Whether it’s multi-axis machining, adaptive control algorithms, or real-time monitoring, we tailor the control interface to meet the exact requirements of each application.

Customized Workholding Solutions: The ability to securely hold workpieces during machining is essential for achieving accurate results. We offer a range of customizable workholding options, including chucks, fixtures, and pallet systems, designed to accommodate diverse part geometries and sizes.

Specialized Tooling: With our in-house tooling capabilities, we can develop customized cutting tools optimized for specific materials and machining operations. From high-speed steel end mills to diamond-coated inserts, we tailor tooling solutions to maximize performance and longevity.

Integration of Automation: Automation plays a key role in enhancing productivity and reducing cycle times. Our CNC machines can be integrated with robotic systems, pallet changers, and conveyor systems to automate material handling, tool changing, and other repetitive tasks, allowing manufacturers to achieve greater efficiency and throughput.

Application-Specific Programming: Our team of experienced engineers works closely with customers to develop customized machining strategies tailored to their unique applications. Whether it’s optimizing tool paths, minimizing machining time, or maximizing surface finish quality, we leverage advanced CAM software to fine-tune every aspect of the machining process.

In the ever-evolving world of manufacturing, customization is the key to unlocking new possibilities and staying ahead of the competition. By customizing CNC machines for specific needs, manufacturers can achieve unparalleled levels of precision, productivity, and flexibility.

At Jaewoo Machines, we are committed to partnering with our customers to deliver tailor-made solutions that empower them to succeed in their respective industries. Whether it’s CNC milling, turning, or grinding, our comprehensive range of machines and customization capabilities ensures that we can meet the most demanding requirements with confidence. Contact us today to learn more about how we can customize CNC machines to address your specific needs and take your manufacturing operations to the next level.

Jaewoo Machines: Pioneers in Customizable CNC Solutions

At Jaewoo Machines, we understand the unique requirements of modern manufacturing. With our commitment to innovation and excellence, we offer a range of CNC machines, including Vertical Machining Centers (VMC), Horizontal Machining Centers (HMC), and Dual-Turret Turning Centers (DTC), designed to meet the diverse demands of our customers. What sets us apart is our unwavering dedication to customization, empowering businesses to achieve unparalleled efficiency and cost savings.

Tailoring Solutions to Your Needs

Gone are the days of settling for off-the-shelf solutions that fail to address specific production challenges. With Jaewoo Machines, you have the freedom to customize your CNC machines according to your exact requirements. Whether you need enhanced precision, increased throughput, or specialized capabilities, our team of experts works closely with you to understand your needs and develop tailored solutions that optimize your manufacturing processes.

From modifying spindle speeds and tool configurations to implementing advanced automation features, we leverage cutting-edge technology and industry expertise to design CNC machines that align perfectly with your production goals. Our flexible approach ensures that you receive a solution that not only meets your current needs but also adapts seamlessly to future requirements, providing long-term value and competitiveness.

Reducing Costs, Maximizing Efficiency

In today’s competitive marketplace, cost optimization is essential for sustainable growth. Recognizing this, Jaewoo Machines is committed to helping businesses reduce production costs without compromising on quality or performance. Our customizable CNC machines are engineered to enhance efficiency and productivity, enabling you to streamline operations and minimize wastage.

Why Customizable CNC Machines Are Essential for Modern Manufacturing?

In the realm of modern manufacturing, the need for customizable CNC (Computer Numerical Control) machines has become increasingly apparent. These versatile machines offer a plethora of benefits that cater to the diverse and evolving requirements of today’s industrial landscape. Let’s delve into why customizable CNC machines are not just desirable but essential for businesses aiming to thrive in the competitive market.

Precision Tailored to Specific Needs

One of the primary reasons why customizable CNC machines are indispensable is their ability to deliver precision tailored to specific needs. Every manufacturing task comes with its unique set of challenges, whether it’s achieving tight tolerances, handling exotic materials, or producing complex geometries. Off-the-shelf CNC machines may not always suffice to meet these demands. By customizing CNC machines, manufacturers can fine-tune parameters such as feed rates, spindle speeds, and tool paths to ensure optimal performance for each application. This precision engineering translates into higher quality products, reduced scrap, and ultimately, greater customer satisfaction.

Enhanced Productivity and Efficiency

Customizable CNC machines are not just about precision; they’re also about boosting productivity and efficiency. Time is money in the manufacturing world, and any opportunity to reduce cycle times and increase throughput is invaluable. With customization, manufacturers can optimize machining processes to minimize idle time, maximize cutting speeds, and automate repetitive tasks. Whether it’s integrating robotic loading systems, implementing advanced tool management solutions, or optimizing workholding configurations, customization enables manufacturers to streamline workflows and extract maximum efficiency from their CNC machines.

Adaptability to Changing Requirements

In today’s fast-paced market, flexibility is paramount. Businesses need to adapt quickly to changing customer demands, market trends, and technological advancements. Customizable CNC machines offer the flexibility to evolve alongside these changes. Whether it’s reconfiguring machine setups for new product lines, retrofitting additional features to accommodate emerging technologies, or upgrading control systems for enhanced functionality, customization ensures that CNC machines remain relevant and adaptable to evolving requirements. This adaptability not only future-proofs manufacturing operations but also provides a competitive edge in an ever-changing landscape.

Cost-Effectiveness in the Long Run

While the initial investment in customizable CNC machines may seem higher than off-the-shelf alternatives, the long-term benefits far outweigh the costs. Customization allows manufacturers to optimize machine performance for their specific applications, leading to reduced scrap, lower production costs, and higher profitability in the long run. Additionally, the ability to extend the lifespan of CNC machines through upgrades and retrofits helps amortize the initial investment over time, making customization a cost-effective strategy for maximizing return on investment.

Conclusion

In conclusion, customizable CNC machines are indispensable tools for modern manufacturing. From delivering precision tailored to specific needs to enhancing productivity, adaptability, and cost-effectiveness, customization offers a myriad of benefits that are essential for staying competitive in today’s market. At Jaewoo Machines, we understand the importance of customization in empowering manufacturers to achieve their goals. Contact us today to learn more about how our customizable CNC machines can revolutionize your manufacturing operations and propel your business to new heights of success.