CNC vs. Manual Machining: Unveiling Advantages and Diverse Applications

In the realm of precision manufacturing, two distinct methodologies stand out: CNC machining and manual machining. Each approach brings its own set of advantages, catering to diverse applications across various industries. Let’s delve into the world of these machining techniques, comparing their benefits and exploring where they shine in today’s manufacturing landscape.

In the world of manufacturing, two stalwarts stand tall: CNC machining, the epitome of precision and automation, and manual machining, the realm of hands-on expertise and adaptability. Exploring the dichotomy between these techniques unveils a fascinating tapestry of strengths and applications. Our journey navigates through the intricate world of CNC and manual machining, uncovering their unique advantages and the diverse landscapes they thrive in.

CNC machining, governed by precise algorithms and digital commands, revolutionizes mass production with unparalleled accuracy. Its realm encompasses industries demanding intricate designs and consistent output, from automotive engineering to medical device manufacturing. On the other hand, manual machining, guided by the skilled hands of craftsmen, celebrates adaptability and artisanal finesse. It finds its niche in custom fabrication, prototyping, and tasks requiring quick adjustments.

However, the convergence of these methodologies paints an intriguing picture. As industries seek both precision and customization, the fusion of CNC’s accuracy with manual dexterity emerges as a compelling force. Our exploration uncovers not just their individual merits but also the harmonious marriage that bridges their differences, propelling the manufacturing world forward through innovation and versatility.

Understanding CNC Machining

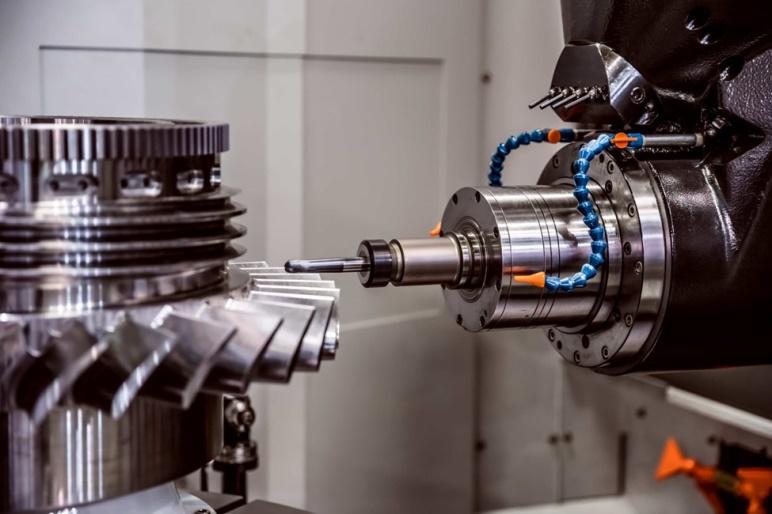

CNC machining involves using computerized systems to control machining tools, such as lathes, mills, and routers. It relies on CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to translate digital designs into precise, automated movements.

Benefits of CNC Machining

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining stands as the beacon of precision and efficiency. Its seamless fusion of technology and craftsmanship yields a plethora of benefits that revolutionize the production process.

1. Unmatched Precision and Consistency

Imagine crafting intricate components with a precision that’s beyond human capability. CNC machines execute every cut, drill, or mill with unparalleled accuracy, ensuring each piece is an exact replica of the last. The consistency across large production runs is simply unmatched, leading to superior quality and uniformity in every part.

2. Complexity Made Simple

Complex geometries and intricate designs? Not a challenge for CNC machining. From aerospace components with intricate curves to detailed molds for medical devices, CNC machines turn complexity into simplicity. They effortlessly replicate even the most intricate designs with utmost accuracy, making the impossible, possible.

3. Enhanced Efficiency and Productivity

The marriage of automation and precision translates into boosted productivity. CNC machines operate round the clock with minimal human intervention, reducing manual errors and significantly cutting down production time. What used to take days can now be achieved in hours, driving efficiency to new heights.

4. Versatility and Adaptability

Versatility is the name of the game in CNC machining. With the right programming, these machines can work on a wide array of materials—from metals to plastics—with ease. Their adaptability allows for quick adjustments and changes in production, catering to diverse manufacturing needs.

5. Cost-Effectiveness and Waste Reduction

Efficiency isn’t just about speed; it’s about savings too. CNC machining optimizes material usage, minimizing waste and reducing overall production costs. The precision in cutting ensures minimal material wastage, making it a financially savvy choice for manufacturers.

6. Innovation and Future-Proofing

As technology evolves, so does CNC machining. With continuous advancements, these machines are at the forefront of innovation in manufacturing. They adapt to newer techniques and materials, making them a future-proof investment for businesses.

Applications of CNC Machining

Automotive Industry: From engine components to intricate parts, CNC machining delivers precision and reliability crucial in automotive manufacturing.

Aerospace Sector: Crafting aerospace-grade components demands high precision and strict tolerances, making CNC machining an ideal choice.

Medical Device Manufacturing: In the production of medical implants and devices requiring high accuracy, CNC machining ensures impeccable quality.

Unveiling Manual Machining

Manual machining involves the use of manual tools operated by skilled machinists. It relies on manual control, requiring hands-on skill and experience to operate lathes, mills, grinders, and other equipment.

Benefits of Manual Machining

In a world where machines rule the roost, manual machining stands tall as a testament to craftsmanship and adaptability. Let’s uncover the unique perks that make this hands-on approach a beloved cornerstone of manufacturing.

1. Craftsmanship and Flexibility

Picture this: a seasoned machinist working their magic on a lathe, shaping metal with precision. That’s the beauty of manual machining—it’s like an art form. Skilled hands adapt swiftly to changes, making it perfect for those unique, custom jobs that need a personal touch.

2. Versatility Across Materials

From hard metals to softer alloys, manual machinists wield their expertise across a wide range of materials. It’s like having a toolbox filled with skills honed over years—ready to tackle any material that comes their way.

3. Human Touch and Experience

There’s something special about hands-on experience. These machinists have a feel for the materials that no machine can replicate. It’s that gut instinct and years of practice that often lead to innovative solutions and flawless craftsmanship.

4. Tailored Solutions, Cost-Effectively

When it comes to small batches or unique parts, manual machining often saves the day. No need for extensive setup or programming—these experts dive right in, crafting custom solutions without breaking the bank.

5. Swift Prototyping and Adaptations

In the race for innovation, manual machining offers a sprinter’s advantage. Need a quick prototype or immediate changes? These machinists can whip up adjustments on the spot, fueling rapid progress and testing new ideas.

6. Expertise in Repair and Maintenance

Think of them as the repair wizards. When machinery needs a fix, manual machinists are the heroes. They assess, modify, or recreate components with finesse, keeping things running smoothly.

In a world where automation reigns, manual machining is like the trusted old friend—reliable, adaptable, and filled with wisdom. It might not boast the flashy precision of CNC, but its human touch and adaptability ensure it remains a treasured asset in the manufacturing world.

Applications of Manual Machining

Prototype Development: Manual machining offers a cost-effective solution for initial prototypes and small-scale production runs.

Custom Fabrication: Industries requiring unique or customized components, like restoration or specialty parts, benefit from the adaptability of manual machining.

Repair and Maintenance: Manual machining skills shine in repair and refurbishment tasks, where flexibility and hands-on expertise are critical.

Where Both Techniques Merge

While CNC and manual machining have their distinct strengths, they often complement each other in manufacturing processes:

Hybrid Approach

Some manufacturing workshops embrace a hybrid model, integrating both CNC and manual techniques. This approach maximizes the benefits of each method. For instance:

CNC Precision, Manual Finesse: CNC machines excel in precise, repetitive tasks. However, for specific intricate or custom components requiring a human touch, skilled machinists intervene manually to fine-tune details or perform specialized adjustments that automated systems might find challenging.

Skill Enhancement

Machinists skilled in both CNC and manual machining bring a broader spectrum of expertise to the table. This duality enables them to choose the most suitable approach for a particular task:

Leveraging Skill Sets: A machinist proficient in both techniques can leverage CNC’s precision for certain aspects while utilizing their manual expertise for nuanced adjustments or customization, optimizing the manufacturing process.

Prototyping and Customization

In scenarios requiring prototyping or customization, the integration of CNC and manual methods provides a well-rounded approach:

CNC for Precision, Manual for Flexibility: CNC machines can swiftly produce accurate prototypes. Yet, manual techniques offer the flexibility to make immediate alterations or test unconventional ideas without the constraints of programming or setup, facilitating rapid iterations.

Maintenance and Repair

When it comes to refurbishing or repairing parts, the marriage of CNC and manual machining expertise becomes crucial:

CNC Precision, Manual Expertise: CNC machines might not adapt readily to repairs. However, machinists proficient in manual techniques can assess, modify, or recreate components using their hands-on experience, ensuring efficient repair and maintenance tasks.

Adaptive Innovation

Innovative solutions often emerge at the intersection of both methodologies:

Fusion for Innovation: The collaboration of CNC’s accuracy with manual dexterity sparks innovative approaches. This fusion fosters creativity, allowing for unconventional problem-solving and unique solutions that draw from the strengths of both techniques.

The merging of CNC and manual machining isn’t about one method overshadowing the other; instead, it’s about harnessing the best of both worlds. It emphasizes adaptability, precision, and the leveraging of human expertise alongside technological advancements to optimize the manufacturing process.

Conclusion

CNC and manual machining each carve a unique niche in the manufacturing ecosystem. While CNC dominates in mass production and precision, manual machining thrives in adaptability and craftsmanship. The future of manufacturing lies in harnessing the strengths of both methodologies, leveraging automation for efficiency and embracing skilled craftsmanship where the human touch excels.

As industries evolve and demands diversify, the synergy between CNC and manual machining continues to drive innovation, delivering quality, precision, and adaptability across a spectrum of manufacturing applications.