The Role of AI in CNC Machining: How artificial intelligence is shaping the industry

Introduction

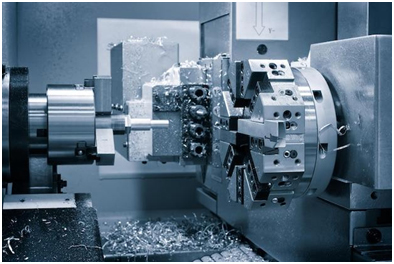

In the world of manufacturing, CNC (Computer Numerical Control) machining stands as a testament to technological evolution, delivering precision and efficiency in the production process. With the advent of Artificial Intelligence (AI), this field is witnessing a transformative shift, ushering in a new era of innovation and capability. This blog explores how AI is revolutionizing CNC machining, shaping the future of this industry.

Background of CNC Machining

CNC machining has been a cornerstone of manufacturing for decades. Originating from the basic numerical control systems of the mid-20th century, it has evolved into a sophisticated technology. Traditional CNC machining faced challenges like manual programming, limited flexibility, and the need for constant human supervision.

The integration of AI into CNC machining marks a pivotal shift. AI algorithms have started to automate complex processes, reducing the reliance on manual intervention. This transition not only addresses the traditional challenges but also opens new avenues for innovation.

Key Benefits of AI in CNC Machining

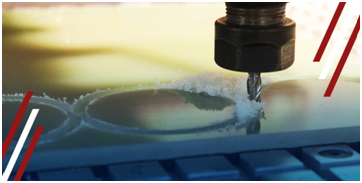

Precision and Accuracy: AI enhances the precision of CNC machines, reducing errors and improving product quality.

Efficiency and Speed: AI-driven machines optimize production processes, leading to faster turnaround times.

Predictive Maintenance: AI algorithms predict machine failures before they occur, minimizing downtime.

Customization and Flexibility: AI enables greater flexibility in production, allowing for more customized designs.

How Artificial Intelligence Is Shaping The Industry?

Artificial Intelligence (AI) is significantly shaping various industries by introducing new capabilities, efficiencies, and ways of working. Here’s an overview of how AI is impacting different sectors:

Manufacturing: AI in manufacturing, including CNC machining, is revolutionizing production lines. It enhances precision, optimizes production schedules, predicts maintenance needs, and enables the production of complex and custom designs with greater efficiency.

Healthcare: AI is transforming healthcare with advancements in diagnostic tools, personalized medicine, and patient care management. AI algorithms assist in early disease detection, analyze medical images with high precision, and support the development of targeted treatments.

Finance: In the finance sector, AI is used for algorithmic trading, fraud detection, and risk management. It also personalizes customer experiences in banking services and enhances financial advisory services with robo-advisors.

Retail: AI in retail is changing the way consumers shop. It powers recommendation engines, optimizes inventory management, provides personalized shopping experiences, and enhances customer service through chatbots.

Transportation and Logistics: AI improves efficiency in transportation through route optimization, predictive maintenance, and autonomous vehicles. In logistics, AI is crucial for supply chain management, forecasting demand, and automating warehouses.

Agriculture: In agriculture, AI aids in crop monitoring, predictive analysis for crop diseases, and optimizing farming practices. It also plays a role in precision farming, which helps in efficient use of resources and increasing crop yields.

Energy: AI helps in optimizing energy usage and maintenance in renewable energy sectors. It’s used for predictive maintenance of infrastructure and for optimizing grid operations in electricity networks.

Education: AI enhances personalized learning experiences, automates administrative tasks for educators, and provides tools for adaptive learning and assessment.

Customer Service: AI-driven chatbots and virtual assistants are increasingly being used for customer service, providing 24/7 support and handling routine inquiries, which improves efficiency and customer satisfaction.

Entertainment and Media: In the entertainment industry, AI is used for content recommendation, personalization, and even in the creation of art and music. It helps media companies to analyze viewer preferences and tailor content accordingly.

Real Estate: AI in real estate assists in property valuation, predictive analytics for market trends, and enhances customer experiences through virtual property tours and automated customer interactions.

Cybersecurity: AI plays a critical role in cybersecurity by identifying and responding to threats in real time. It helps in analyzing patterns and predicting potential security breaches.

In each of these industries, AI is not just a tool for automation but also a driver of innovation, enabling new products and services, and transforming existing business models. The impact of AI is widespread, offering both opportunities and challenges as industries adapt to incorporate these advanced technologies into their operations.

Challenges and Limitations of AI in CNC Machining

Despite its advantages, AI integration in CNC machining faces challenges like high initial costs, the need for skilled personnel, and ongoing debates over AI ethics in automation and workforce displacement.

The integration of Artificial Intelligence (AI) into CNC (Computer Numerical Control) machining brings numerous advantages, but it also presents several challenges and limitations. Understanding these is crucial for industries looking to adopt this technology. Here are the key challenges and limitations:

High Initial Investment and Operating Costs: One of the primary challenges is the significant investment required to integrate AI into existing CNC systems. This includes the cost of acquiring advanced AI software, upgrading machinery, and potentially altering infrastructure. Additionally, ongoing expenses related to software updates, maintenance, and training can be substantial.

Complexity of Implementation: Implementing AI in CNC machining is not just a matter of installing new software. It often requires a complete overhaul of existing processes. This complexity extends to integrating AI with various types of machinery, each with its own specifications, and ensuring compatibility and efficient operation.

Data Management and Security: AI systems rely heavily on data for machine learning and decision-making processes. Managing this vast amount of data, ensuring its quality, and protecting it from security breaches pose significant challenges.

Skill Gap and Workforce Training: The introduction of AI in CNC machining requires a workforce skilled in both traditional machining and AI technology. There is often a skill gap in the industry, as many current operators and technicians may not be familiar with AI. This necessitates extensive training and sometimes hiring new staff with the requisite expertise, which can be costly and time-consuming.

Reliability and Maintenance: While AI can predict and reduce machine failures, the technology itself is not immune to malfunctions. AI systems can be complex and may require specialized knowledge to maintain and repair, which can lead to increased downtime and maintenance costs.

Ethical and Employment Concerns: The automation brought about by AI integration can lead to concerns about job displacement. There is a fear that machines might replace human workers, leading to unemployment in certain sectors. Additionally, there are ethical considerations regarding the extent to which decision-making should be automated in manufacturing processes.

Adaptability and Flexibility: While AI improves efficiency, there can be challenges in terms of adaptability and flexibility. AI systems might excel in repetitive tasks but can struggle with unexpected situations or tasks that require human intuition and creativity.

Regulatory and Compliance Issues: Integrating AI into CNC machining can also bring regulatory challenges. Compliance with industry standards and regulations, especially when they are evolving alongside emerging technologies, can be a complex and ongoing process.

Integration with Legacy Systems: Many manufacturing facilities use older CNC machinery that may not be readily compatible with modern AI technologies. Upgrading these systems or integrating them with AI can be technically challenging and expensive.

Quality Assurance: Ensuring consistent quality can be a challenge when transitioning to AI-driven processes. AI algorithms might optimize for efficiency or material use, which might not always align with the desired quality standards, especially in industries with very stringent specifications.

The Future of AI in CNC Machining

The future of AI in CNC machining is promising, with potential advancements like fully autonomous factories and further customization capabilities. As technology advances, AI is expected to become more integrated into every aspect of CNC machining.

Increased Automation and Efficiency: AI will continue to drive automation in CNC machining, making processes more efficient and precise. With advancements in machine learning algorithms, CNC machines will become more adept at handling complex tasks, reducing the need for human intervention and minimizing errors.

Predictive Maintenance and Self-Diagnostics: AI systems will become more sophisticated in predicting machine failures and maintenance needs, leading to reduced downtime and increased longevity of equipment. Machines will be able to diagnose their own issues and even order replacement parts autonomously.

Enhanced Customization and Design: AI will enable more advanced customization options in CNC machining. By analyzing vast datasets, AI can assist in designing products that are optimized for functionality, aesthetics, and cost. This will particularly benefit industries where customization is key, such as aerospace and automotive.

Improved Material Utilization and Sustainability: AI algorithms will optimize material usage, reducing waste and enhancing sustainability in manufacturing processes. This is crucial in an era where resource efficiency and environmental impact are major considerations for any industry.

Integration with the Internet of Things (IoT): The combination of AI and IoT will lead to smarter factories where CNC machines are interconnected and communicate seamlessly. This integration will facilitate real-time monitoring and adjustments, leading to more responsive and adaptable manufacturing environments.

Advanced Quality Control: AI will significantly improve quality control in CNC machining. Through advanced image recognition and data analysis, AI systems will be able to detect defects and quality issues with greater accuracy and speed than human inspectors.

Enhanced Safety: As AI systems become more intelligent, they will play a crucial role in ensuring safety in the manufacturing environment. AI can monitor and predict potential hazards, reducing the risk of accidents and improving overall workplace safety.

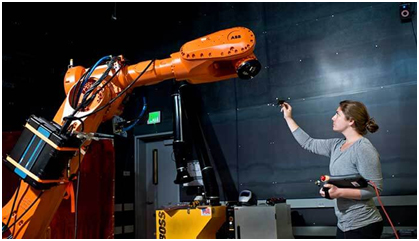

Collaborative Robotics (Cobots): The use of AI-driven collaborative robots (cobots) in CNC machining will become more prevalent. These cobots will work alongside human operators, taking on repetitive or dangerous tasks while enhancing productivity and safety.

Real-time Data Analysis and Decision Making: With AI, CNC machines will be able to process and analyze data in real time, making on-the-fly adjustments to optimize machining processes. This will lead to smarter, data-driven decision-making in manufacturing.

Training and Skill Development: As AI technologies evolve, there will be a greater need for skilled professionals who can work alongside these advanced systems. This will likely lead to new educational and training programs focusing on the intersection of AI, robotics, and CNC machining.

Global Supply Chain Integration: AI will facilitate tighter integration of CNC machining within global supply chains, allowing for more efficient and responsive production cycles that are better aligned with market demands and logistics.

Conclusion

AI is undoubtedly reshaping the CNC machining industry, driving it towards a more efficient, precise, and flexible future. While challenges remain, the integration of AI holds immense potential for innovation and growth in this field.