Introduction

The CNC turning machine is a modern manufacturing emblem that represents automation and precision, changing the production of anything from complex medical gadgets to aircraft components. However, how did we come to achieve this amazing union of mechanical artistry and computer technology?

The history of the CNC turning machine takes us on a trip through decades of invention and development, from the earliest days of numerical control to the modern wonders of high accuracy that are computer-driven. This voyage is proof of the human spirit’s tenacity and our never-ending search for manufacturing techniques that are more accurate, efficient, and adaptable.

In this blog, we take readers on a historical tour of the development of CNC turning machines, from their modest origins as experimental devices in the 1950s to the state-of-the-art technologies that currently support a wide range of sectors, including aviation, healthcare, and more.

Come along as we delve into the history of innovation and examine the significant turning points, cutting-edge ideas, and innovative minds that have shaped the development of CNC turning machines. This intriguing voyage sheds light on the technology used in modern manufacturing and its long-lasting effects on our contemporary society.

Brief of History of CNC Turning Machines

The machining method used in CNC machining was created in the eighteenth century. The first “turning the machine with a metal frame” was actually created in 1751, and it was the first in a long line of devices designed to mechanically do more exact tasks than could be done by hand. This signified the start of the industrial revolution.

However, the development of automation was not addressed until the Cold War. At that time, the U.S. Navy had contracted with Parsons Works to boost the output of their helicopter blade manufacturing line. The axes of the machinery used to make these blades were then motorized by John T. Parsons. He investigated the potential for computer control of these devices while working at IBM. This served as the foundation for the CNC machining process.

Cincinnati Milacron Hydrotel, the first CNC milling machine, was created in 1952 by Richard Kegg and MIT. He submitted a patent application for a “Motor Controlled Apparatus for Positioning Machine Tool” in 1958, five years later. This marked the technology’s introduction to the market.

Detailed History of CNC Turning Machines

Early Development Phase – 1950s

The 1950s are when CNC technology first began to emerge. Researchers and engineers started experimenting with the concept of utilizing computers to operate machinery around this time. Large and intricate, the first CNC machines were mostly employed in aerospace and military fields.

Numerical Control (NC) – Late 1950s

The notion of Numerical Control (NC) first appeared in the late 1950s. Thanks to this technique, machine tools could be automatically controlled using a set of numerical codes that are commonly called “G-codes.” CNC technology advanced significantly with the introduction of NC.

CNC Development – 1960s

Further developments in CNC technology occurred in the 1960s with the advent of minicomputers and more complex control systems. CNC machines began to become more and more common in production sectors like aerospace and automotive.

CNC Turning Machines – 1970s

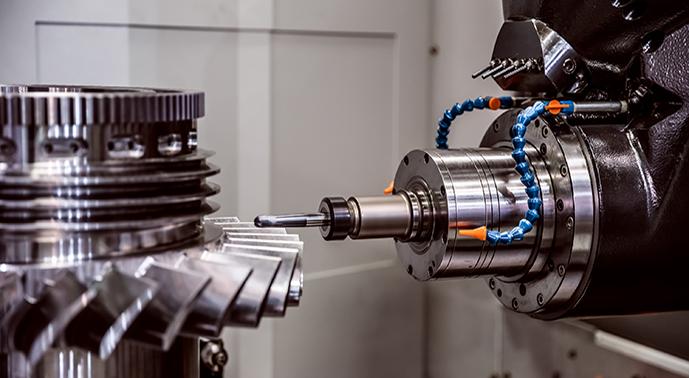

CNC turning machines had grown more common by the 1970s. These devices may turn objects, which involves rotating a work piece while a cutting tool removes material to generate conical or cylindrical shapes. This technology was essential in increasing machining efficiency and precision.

CNC Advancements – 1980s

Significant advances in CNC technology were made in the 1980s. The interface between computers and CNC machines developed further, and control systems got easier to operate. The changeover from earlier tape-based methods to computer-controlled CNC machining occurred throughout this decade.

CAD/CAM Integration – 1990s

Software for computer-aided design (CAD) and computer-aided manufacturing (CAM) was integrated with CNC machines in the 1990s. The capabilities of CNC turning machines were further enhanced by this connection, which made it possible to design more intricate parts and program them more quickly.

CNC Precision – 21st Century

The development of CNC turning machines has proceeded throughout the twenty-first century. Modern CNC turning machines come equipped with advanced tooling, multi-axis capability, and high-speed machining as standard features. These devices create complex and accurate parts for a variety of businesses, including the medical sector.

Emergence of Industry 4.0

These days, CNC turning machines are frequently associated with the larger Industry 4.0 trend, centered around the amalgamation of automation, data analytics, and smart technology. Network connectivity enables predictive maintenance, remote programming, and real-time monitoring of CNC machines.

Industries it has served till 2023

General Machinery

Globally, 86 million parts and tools are produced every day on average. These vary in size and complexity from the tiniest and most basic designs to the larger and more intricately designed tools. The engineering sector is highly dependent on things like doing work more quickly, using less energy, cutting costs, and—above all—supplying equipment with greater precision.

Currently, human manual processing has been replaced by machine processing. It is easier for enterprises to offer virtually accurate deliveries on schedule thanks to computerized algorithms. It is currently necessary to keep up with the development of technology. The design and processing of industrial equipment have been altered by CNC machines.

The finest precision may now be attained for less money thanks to CNC equipment. In addition to processing and creating larger equipment, CNC machines are also capable of processing the tiniest tools. There is nothing in between that a CNC machine cannot process, from a tiny screw used in domestic appliances to a machinery clip used in industrial machinery.

Railway Machinery

Over 20,000 passenger trains operate on long-distance and suburban routes every day, making the Indian Railway network the fourth largest rail network globally in terms of area. Given the vastness of India’s railway network—67,368 kilometers—accuracy is the most sought-after attribute in the sector. It is necessary to approach the design, functioning, operations, etc. with a meticulous eye. It is necessary to pay close attention to little details and expertly build the machinery that provides the engine with smooth operation and efficiency.

Twenty million people use the rail networks every day on average. These folks rely on the motor engine for their safety and security. A small error in size or shape could result in a more serious unfortunate circumstance. Acquiring the necessary specs is made easier by CNC machines. It provides accurate engineering and does not overlook any details.

The necessary equipment is designed and processed with the aid of CNC machines, ensuring the machine operates smoothly in the end. People who travel by train can be guaranteed of their safety and security because CNC machines can maintain the necessary precision.

Aeronautical Industry

Aircraft are to be constructed with the highest precision, whether they are private jets intended for family vacations in the sky or commercial aircraft capable of transporting hundreds of passengers. The outside body, the engine, and the cockpit’s computer-controlled equipment should all be produced with accuracy and speed. It ought to be carried out in a way that ensures both great performance and safety. The aviation industry makes substantial use of CNC turning machines.

Some of these include the construction of a minuscule component that fits inside the engine and increases fuel efficiency, a computer chip that is only a few micrometers long, and a micron-thick device that is installed inside a radar to guide the aircraft through a build-up of dense clouds and safely land at its destination. Airlines are following stringent security protocols in response to a growing number of regrettable incidents and breakdowns in air traffic control management. For this reason, the aerospace industry is experiencing a sharp increase in demand for high-precision engineering. This level of precision can be achieved by CNC turning machines.

Agriculture Machinery

One sector that most likely stands to gain the most from technological advancement is agriculture. We can easily tend to the nation’s expanding population if we have improved tractors, potato planters, air seeders, precision drills, transplanters, fertilizer spreaders, manure spreaders, pesticide sprayers, and harvesters operating under our control. Here’s where CNC turning machines come into play.

Large and small agricultural manufacturers can benefit from the high precision, low maintenance, and long lifespan of CNC turning machines, which will boost their production and lessen their reliance on human labor. The agricultural machinery market is projected to expand at a compound annual growth rate (CAGR) of 6.3% between 2018 and 2023, or from Rs. 857 billion in 2017 to Rs. 1,245 billion in 2023, as a result of the agriculture sector’s explosive growth in India.

Conclusion

Since its invention in the 1950s, the CNC turning machine has advanced significantly. Since its inception as experimental technology in the military and aerospace industries, it has permeated almost every aspect of contemporary manufacturing. The modern world is being shaped by CNC turning machines, which are at the center of numerous industries like healthcare, aerospace, automotive, and many more.

We find ourselves at the nexus of mechanical precision and human invention as we wrap up our tour through the history of CNC turning machines. From the earliest days of numerical control to the most sophisticated CNC technology available today, the development of these amazing machines is a tale of unceasing invention and advancement.

Ultimately, the CNC turning machine represents human progress and is more than just a tool. It’s evidence of what we can achieve when we harness the power of technology and human ingenuity. Additionally, the CNC turning machine will always be a crucial part of the continuing narrative of human progress as long as there are obstacles to overcome and innovations to seek.